Industry news|2022-03-22| admin

Planetary gearbox is widely used in daily equipment manufacturing. The purpose of using it is to reduce the output speed and increase the output torque. It can be divided into single-stage and multi-stage according to the number of gear carrier stages. For better understanding, the speed ratio of the single-stage gearbox is generally smaller, and the speed ratio of the two-stage gearbox will be larger. times decrease, torque increases exponentially.

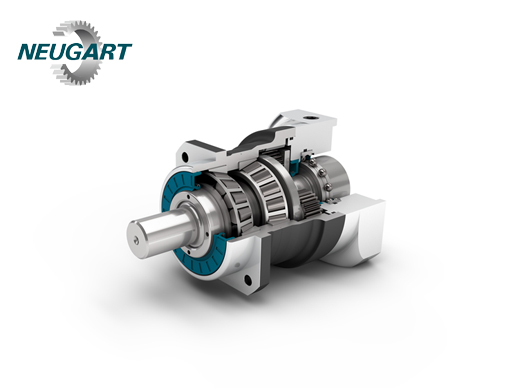

The main application of the gearbox in the industrial automation market is the planetary gearbox. The planetary gearbox is widely used in servo, stepping, DC and other transmission systems due to its small size, high transmission efficiency, wide reduction scale, and high precision. The planetary gearbox is classified as a precision gearbox. The planetary gearbox has a small return clearance and high precision.

At present, the traces of artificial intelligence can be found in the fields of catering, home furnishing, industry, public management services, and fire protection. Robots have entered one of our lives, and the development has opened the era of intelligent technology! Therefore, the demand for precision planetary gearboxs for industrial robots continues to rise. Promoted a substantial increase in the gearbox profession. The demand for planetary gearboxs in metallurgy, electric power, automation, construction machinery, industrial production machinery and other industries is also increasing.

The internal gear of the planetary gearbox has the characteristics of small size, light weight, high bearing capacity, long service life, stable operation, low noise, large output torque, large speed ratio, high efficiency and safe performance. It has the characteristics of power splitting and multi-tooth meshing. It is a new type of gearbox with wide versatility. It is suitable for industrial sectors such as lifting and transportation, construction machinery, metallurgy, mining, petrochemical, construction machinery, light industry and textile, medical equipment, instrumentation, automobiles, ships, weapons and aerospace.

The weight of the planetary gear transmission is generally proportional to the weight of the gear, and the weight of the gear has a great relationship with its material and heat treatment hardness. For example, under the same power, the weight of the carburized and quenched gear will be about 13 of that of the quenched and tempered gear. The benefit of the quenched and tempered treatment is to increase the resistance of the gear. Therefore, according to the structural characteristics of the planetary gear gearbox and the load properties of the gears, hardened gears should be widely used. There are many heat treatment methods for obtaining hardened gears, such as surface quenching, overall quenching, carburizing quenching, nitriding, etc., which should be selected according to the characteristics of the planetary gear gearbox.

Precision planetary gearbox is an important part of robotic equipment. It can be seen that the demand for automation is driving the development of the intelligent robot industry, and the skills of the automation industry are leading the technical and economic progress of the precision planetary gearbox, and the two have truly completed the integrated development.

1. The planetary gearbox can effectively protect the long-term work of the motor

The use of planetary servo gearbox can effectively protect the long-term work of the motor, and support the motor to accept greater torque during work, while preventing the motor from being damaged due to overload.

2. Planetary gearbox can save operating costs to the greatest extent

Under normal circumstances, if the servo planetary gearbox is not used, the motor will directly take over all the responsibilities. In this case, the service life of the motor will be greatly shortened, and the motor will be damaged within a month, and the use of precision In the case of a servo planetary gearbox, if the bearing capacity is really strong enough to damage the machine, then the damage must be the gearbox rather than the motor, and the maintenance cost of the gearbox is much lower than that of the motor. !

3. The planetary gearbox can reduce the moment of inertia

The use of the helical planetary gearbox can be very useful to reduce the moment of inertia, and the right-angle planetary gearbox can also control the start and stop of the motor in time, and complete the intention of shifting during the process.

4. The planetary gearbox can effectively solve the energy consumption of enterprises

The use of the planetary gearbox can also reduce the current of the motor to the minimum output torque, thus reducing the energy consumption of the enterprise to the minimum extent.

5. The planetary gearbox can reduce the speed of the motor and increase the torque

The use of the gearbox can effectively reduce the speed of the motor and increase the torque, which is also the main function of the planetary gearbox.

The above is an introduction to the advantages of planetary gearboxs in the field of automation. For more information about gearboxs, you can consult Shenzhen Win-drive Automation.